该企业位于广州市,属于典型的亚热带季风气候,常年温暖湿润,夏季高温多雨,冬季温和少雨。年平均气温约22℃,夏季气温常达30℃以上,湿度较高,对生产环境的温湿度控制提出较高要求。广州作为全国重要的服装产业基地之一,产业链完整,设计、生产、销售体系成熟,区域内服装企业竞争激烈,对生产效率和产品品质的要求日益提升。

诚昊服装是一家拥有多年历史的老牌服装企业,具备从面料检验、剪裁、缝制、整烫到成品包装的完整生产工艺。企业共有三栋多层钢筋混凝土结构标准厂房,根据生产流程,车间按功能分层布置,主要包括:面料仓储与检验车间、自动剪裁车间、成衣缝制车间、整烫与定型车间、品质检验与包装车间等。

本次环境改造的重点是成衣缝制车间。该车间人员密集,流水线作业连续性强,原使用的冷风机(环保空调)虽具备一定降温效果,但在广州高温高湿的气候条件下,其降温能力有限,且会增加车间空气湿度,影响缝制面料的物理性能,容易导致线迹不均匀、面料变形等问题。为提高员工舒适度、保障产品品质、增强企业市场竞争力,该企业决定对车间温湿度环境进行系统性改造。

瑞峰环保制冷的方案设计团队综合考虑了以下因素:

1、地理气候特点:广州夏季高温高湿,要求空调系统具备除湿与降温双重能力;

2、车间结构特点:厂房密封性较好,适合采用内循环气流组织方式,避免外界湿热空气影响;

3、空间布局限制:车间面积虽大,但地面设备与生产线布局紧凑,需选用不占用地面空间的安装方式;

4、能效与经济性:在保障效果的前提下,尽可能降低运行成本,提升长期使用性价比。

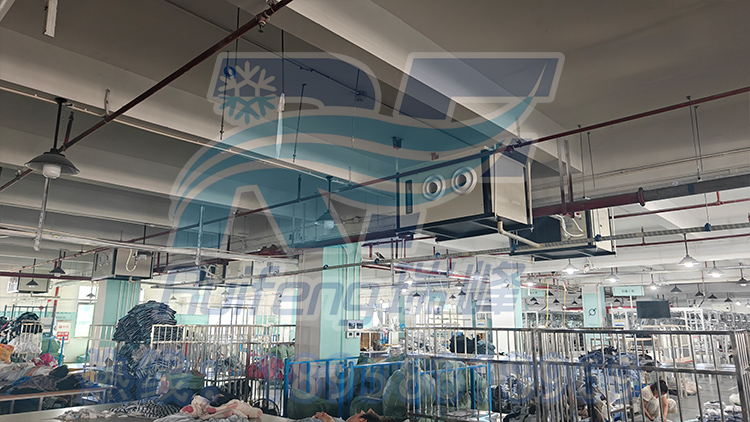

基于以上分析,我们最终为该车间设计了多台大功率吊挂式射流工业省电空调系统。该设备采用吊顶安装,节约地面空间;射流送风方式可实现远距离、大范围均匀送风,避免直吹人体;具备独立温湿度控制功能,可根据车间实际需求灵活调节。

系统投入使用后,车间温湿度始终稳定在舒适范围内,员工工作环境明显改善,疲劳感降低,注意力更加集中,生产效率与缝制质量得到有效提升。此外,温湿度的精确控制也减少了面料受潮、线迹不良等质量问题,为企业长期稳定生产提供了可靠的环境保障。

此次改造看似是设备更新,实则是基于专业分析与长远规划的系统升级。瑞峰团队向企业说明:在广州这类高湿气候地区,传统冷风机不仅无法有效控温,还会加剧湿度累积,对服装生产尤为不利。而工业空调系统具备温湿双控能力,初期投入虽略高,但长期来看,在节能效果、环境稳定性与综合效益方面更具优势,真正实现了从“降温”到“控环境”的升级。

The enterprise is located in Guangzhou, which belongs to a typical subtropical monsoon climate with warm and humid weather throughout the year. The summer is hot and rainy, while the winter is mild and less rainy. The annual average temperature is about 22 ℃, with summer temperatures often reaching over 30 ℃ and high humidity, which puts high demands on temperature and humidity control in the production environment. As one of the important clothing industry bases in China, Guangzhou has a complete industrial chain, mature design, production, and sales systems. The competition among clothing enterprises in the region is fierce, and the requirements for production efficiency and product quality are increasingly increasing.

Chenghao Clothing is a well-established clothing enterprise with many years of history, possessing a complete production process from fabric inspection, cutting, sewing, ironing to finished product packaging. The enterprise has three multi story reinforced concrete structure standard factories. According to the production process, the workshops are arranged in functional layers, mainly including: fabric storage and inspection workshop, automatic cutting workshop, garment sewing workshop, ironing and shaping workshop, quality inspection and packaging workshop, etc.

The focus of this environmental renovation is on the garment sewing workshop. The workshop is densely populated with personnel and has strong continuity in assembly line operations. Although the originally used air cooler (environmentally friendly air conditioner) has a certain cooling effect, its cooling capacity is limited under the high temperature and humidity climate conditions in Guangzhou, and it will increase the humidity of the workshop air, affecting the physical properties of the sewn fabric, and easily causing problems such as uneven stitching and fabric deformation. In order to improve employee comfort, ensure product quality, and enhance the competitiveness of the enterprise in the market, the company has decided to systematically transform the temperature and humidity environment in the workshop.

The design team of Ruifeng Environmental Protection Refrigeration has comprehensively considered the following factors:

1. Geographical and climatic characteristics: Guangzhou has high temperatures and humidity in summer, requiring air conditioning systems to have dual dehumidification and cooling capabilities;

2. Workshop structural characteristics: The factory building has good sealing and is suitable for using internal circulation airflow organization to avoid the influence of external humid and hot air;

3. Space layout limitations: Although the workshop area is large, the ground equipment and production line layout are compact, requiring the use of installation methods that do not occupy ground space;

4. Energy efficiency and economy: While ensuring effectiveness, minimize operating costs and improve long-term cost-effectiveness.

Based on the above analysis, we ultimately designed multiple high-power suspended jet industrial energy-saving air conditioning systems for the workshop. The device is installed on a suspended ceiling to save floor space; The jet air supply method can achieve long-distance and wide range uniform air supply, avoiding direct blowing on the human body; Equipped with independent temperature and humidity control function, it can be flexibly adjusted according to the actual needs of the workshop.

After the system was put into use, the temperature and humidity in the workshop remained stable within a comfortable range, the working environment for employees improved significantly, fatigue was reduced, attention was more focused, and production efficiency and sewing quality were effectively improved. In addition, precise control of temperature and humidity also reduces quality issues such as fabric moisture and poor stitching, providing reliable environmental protection for long-term stable production of enterprises.

This renovation may seem like an equipment update, but it is actually a system upgrade based on professional analysis and long-term planning. The Ruifeng team explained to the company that in high humidity climate areas like Guangzhou, traditional air coolers not only fail to effectively control temperature, but also exacerbate humidity accumulation, which is particularly detrimental to clothing production. Industrial air conditioning systems have the ability to control both temperature and humidity. Although the initial investment is slightly higher, in the long run, they have more advantages in terms of energy-saving effect, environmental stability, and comprehensive benefits, truly achieving the upgrade from "cooling" to "environmental control".

更多案例

客服热线:18958818969

服务热线:13356130717

电子邮件:ruifeng0717@163.com

公司地址:浙江省温州市平阳县万全镇紫来创业园二幢

瑞峰官网:www.wzrfhb.com