一、项目概况

该厂位于浙江温州,地处东南沿海,属亚热带季风气候,四季分明,夏季高温多湿,冬季温和湿润,常年平均湿度较高。此类气候条件对食品生产环境的温湿度控制提出了严格要求。该厂专业生产吐司、面包、糕点及各类蛋糕产品,为周边连锁门店提供每日新鲜烘焙食品,是市民饮食多样化与优质烘焙产品供应的重要环节。

二、车间分类与工艺特点

厂内根据糕点生产流程,划分为两类核心车间:

1、食品生产车间:涵盖原料称量、搅拌、醒发、烘烤等前道工序,配备多功能搅拌机、烤箱、醒发箱、冷藏工作台等设备。

2、食品成型包装车间:负责冷却、裱花、切片、巧克力调温、真空包装等后续工序,配置裱花台、喷砂机、巧克力调温机、包装机等专用设备。

糕点食品不仅满足人们的日常饮食需求,也为现代生活增添了风味与情感体验,是城市食品多样性与生活品质的重要组成部分。尤其在奶油、巧克力等原料处理环节,环境温湿度的精准控制直接关系到产品品质与食品安全。

三、厂房结构与装修特点

厂房为多层钢筋混凝土标准结构,配有采光玻璃窗。其中:

1、生产车间为满足食品级洁净要求,墙面与吊顶均采用不锈钢覆面,易于清洁维护;

2、成型包装车间则在控制成本的同时确保卫生,采用墙面瓷砖装修。

四、方案设计思路

瑞峰技术团队综合考虑多项因素,包括:

1、温州地区夏季高温高湿的气候特点;

2、厂房结构密封性良好,适合采用内循环气流组织方案;

3、车间使用面积紧凑,需选用不占用地面空间的安装方式;

4、空间尺度适中,无需远距离送风,适用轴流机型实现高效节能运行。

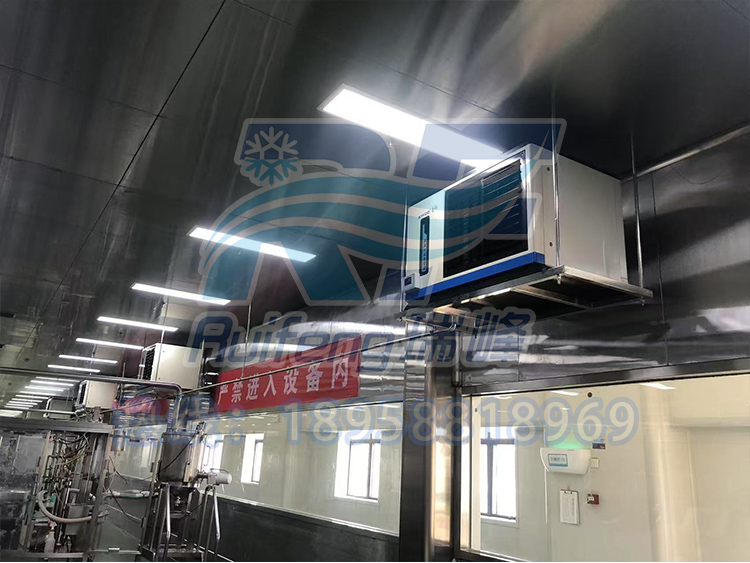

为此,项目整体选用大功率吊挂式工业轴流省电空调系统,并针对不同车间进行差异化设计:

1、在生产车间,因环境密闭、洁净要求高,采用出风柔和、气流分布均匀的轴流式机型,确保温场稳定,避免局部温差影响生产;

2、在成型包装车间,因空间相对开阔、人员流动较大,采用可定点送风的管道式机型,并特别选用食品级不锈钢风管,兼顾送风精准性与清洁卫生要求。

五、实施效果

系统投入运行后,各车间温湿度均达到工艺设计要求:

1、生产车间实现持续均匀降温,保障面团醒发与烘烤环节的稳定性;

2、成型包装车间实现定向温控,确保巧克力调温、奶油成型等工序在适宜环境中进行,有效提升产品一致性与卫生安全水平。

六、项目意义

本项目虽是食品行业案例,但其中体现的环境精准调控、差异化空间设计、卫生级材料应用等系统能力,同样适用于医药、电子、精密加工等对温湿度与洁净度有严格要求的行业场景。瑞峰环保制冷不仅专注于高大空间工业环境调控,也具备应对各类特殊场景、复杂需求的方案设计与实施能力,为客户提供真正贴合生产实际的通风降温解决方案。

1、 Project Overview

The factory is located in Wenzhou, Zhejiang Province, on the southeast coast, with a subtropical monsoon climate and distinct four seasons. The summer is hot and humid, while the winter is mild and humid, with a high average humidity throughout the year. This type of climate condition imposes strict requirements on temperature and humidity control in the food production environment. The factory specializes in producing toast, bread, pastries, and various cake products, providing daily fresh baked goods for surrounding chain stores. It is an important link in the diversification of citizens' diets and the supply of high-quality baked goods.

2、 Workshop classification and process characteristics

According to the pastry production process, the factory is divided into two core workshops:

(1). Food production workshop: covering the previous processes such as raw material weighing, mixing, awakening, baking, etc., equipped with multifunctional mixers, ovens, awakening boxes, refrigeration workbenches and other equipment.

(2). Food molding and packaging workshop: responsible for subsequent processes such as cooling, piping, slicing, chocolate temperature adjustment, vacuum packaging, etc., equipped with specialized equipment such as piping table, sandblasting machine, chocolate temperature adjustment machine, packaging machine, etc.

Pastry food not only meets people's daily dietary needs, but also adds flavor and emotional experiences to modern life, and is an important component of urban food diversity and quality of life. Especially in the processing of raw materials such as cream and chocolate, precise control of environmental temperature and humidity directly affects product quality and food safety.

3、 Characteristics of Factory Structure and Decoration

The factory building is a multi story reinforced concrete standard structure, equipped with skylight glass windows. among which

(1). In order to meet the requirements of food grade cleanliness, the walls and ceilings of the production workshop are covered with stainless steel, which is easy to clean and maintain;

(2). The molding and packaging workshop ensures hygiene while controlling costs, and is decorated with wall tiles.

4、 Design concept of the scheme

The Ruifeng technical team comprehensively considers multiple factors, including:

(1). The climatic characteristics of high temperature and high humidity in Wenzhou area during summer;

(2). The factory structure has good sealing and is suitable for adopting an internal circulation airflow organization scheme;

(3). The workshop has a compact usage area and requires installation methods that do not occupy floor space;

(4). Moderate spatial scale, no need for long-distance air supply, suitable for axial flow models to achieve efficient and energy-saving operation.

For this purpose, the project adopts a high-power suspended industrial axial flow energy-saving air conditioning system as a whole, and carries out differentiated design for different workshops:

(1). In the production workshop, due to the enclosed environment and high cleanliness requirements, a soft and evenly distributed axial flow model is used to ensure stable temperature field and avoid local temperature differences affecting production;

(2). In the molding and packaging workshop, due to the relatively open space and large personnel flow, a pipeline type model with fixed-point air supply is adopted, and food grade stainless steel air ducts are specially selected to balance air supply accuracy and cleanliness and hygiene requirements.

5、 Implementation effect

After the system is put into operation, the temperature and humidity in each workshop meet the process design requirements:

(1). Continuous and uniform cooling is achieved in the production workshop to ensure the stability of dough awakening and baking processes;

(2). The molding and packaging workshop implements directional temperature control to ensure that chocolate temperature control, cream molding and other processes are carried out in a suitable environment, effectively improving product consistency and hygiene and safety levels.

6、 Project significance

Although this project is a case study in the food industry, the system capabilities reflected in it, such as precise environmental control, differentiated space design, and application of hygiene grade materials, are also applicable to industries with strict requirements for temperature, humidity, and cleanliness, such as pharmaceuticals, electronics, and precision machining. Ruifeng Environmental Protection Refrigeration not only focuses on the regulation of industrial environments in high-rise spaces, but also has the ability to design and implement solutions to meet various special scenarios and complex needs, providing customers with ventilation and cooling solutions that truly fit their production needs.更多案例

客服热线:18958818969

服务热线:13356130717

电子邮件:ruifeng0717@163.com

公司地址:浙江省温州市平阳县万全镇紫来创业园二幢

瑞峰官网:www.wzrfhb.com